How to Clean and Maintain Airsoft Guns?

Purchasing an airsoft gun and never cleaning or maintaining it is a lot like purchasing a car and never taking it to a mechanic - it'll work fine for a while, but eventually you are going to run into problems. Not only is cleaning and maintaining airsoft guns essential for extending the lifespan of your costly investment, but it's also essential for optimizing your gun's performance. If you aren't sure how to clean and maintain an airsoft gun, we at RedWolf Airsoft are here to help. In this article, we'll cover everything you need to know about how to clean an airsoft gun, including how to clean your electric airsoft AEG, spring, and gas guns alike.

How Often Should You Clean Your Guns?

It is recommended that you clean your airsoft guns after every period of extended use. That doesn't mean they need to be cleaned every single time you fire them, but if you spend all day at the field putting hundreds of rounds through your gun then it's a good idea to give it a thorough cleaning when you get home. While this may sound like quite the hassle, cleaning an airsoft gun should only take fifteen minutes or so if you use the right tools and follow the right procedures to maintain airsoft guns.

What Tools Will You Need?

Speaking of the right tools, there are a couple of airsoft gun cleaning tools that you will want to be sure and purchase if your gun did not come included with them. The first and arguably most essential airsoft cleaning tool is a barrel cleaning/unjamming rod. In addition to helping you remove BBs that become lodged in your gun's barrel in the event of a jam, this rod also features an attachment point for attaching cleaning patches that will allow you to scrub the inside of your gun's barrel to clean and maintain airsoft guns. Cleaning patches can be purchased from any store that sells airsoft supplies, and you can also use cleaning patches that are designed for real-steel firearms if you cut them down to size. Making your own cleaning patches out of an old t-shirt or other piece of fabric is an option as well.

Many cleaning patches come pre-lubricated with gun oil that will prevent your gun's metal components from rusting. If you don't have pre-lubricated patches, though, you will want to be sure and purchase a bottle of gun oil as well. Finally, you may need tools such as a small screwdriver or set of Allen keys to disassemble your airsoft gun when it's time for a more thorough cleaning.

What are the Most Important Parts to Pay Attention to?

It's worth mentioning first that the specific components inside an airsoft gun will differ from gun to gun. An electric airsoft gun, for example, functions much differently than a spring-powered gun and has different components that must be cared for as part of your gun's regular cleaning and maintenance. For the purpose of this section, though, we are going to focus on the important components/maintenance priorities that are common to all types of airsoft guns. In the next section, we'll dive into more platform-specific cleaning and maintenance procedures.

Gun Barrel Maintenance

The inner barrels of airsoft guns are made out of either steel, aluminum, or brass - all of which are prone to corrosion if they are not kept properly lubricated. This is why it is important to always clean the inner barrel of your airsoft gun using a cleaning patch that has been soaked in gun oil that is designed to prevent corrosion and maintain airsoft guns.

In addition to preventing corrosion, it's also essential to clean your gun's barrel regularly in order to remove any residue or debris that might have built up. When a BB is fired through the gun's barrel, little flakes of plastic often rub off and are left behind. Over time, these flakes of plastic along with any dust or dirt that happens to get inside your barrel can build up and negatively affect the gun's performance. Running a cleaning patch through your barrel after each period of extended use ensures that all of this residue and debris is removed before your next outing.

Exterior Maintenance

Many of the exterior components of an airsoft gun are typically made out of plastic or metal, and these components won't really require a lot of care aside from wiping them down occasionally. However, if there are any exterior components of your gun that are made out of metal, though, you will want to wipe them down gun oil after every use in order to prevent rust and corrosion.

Lubrication

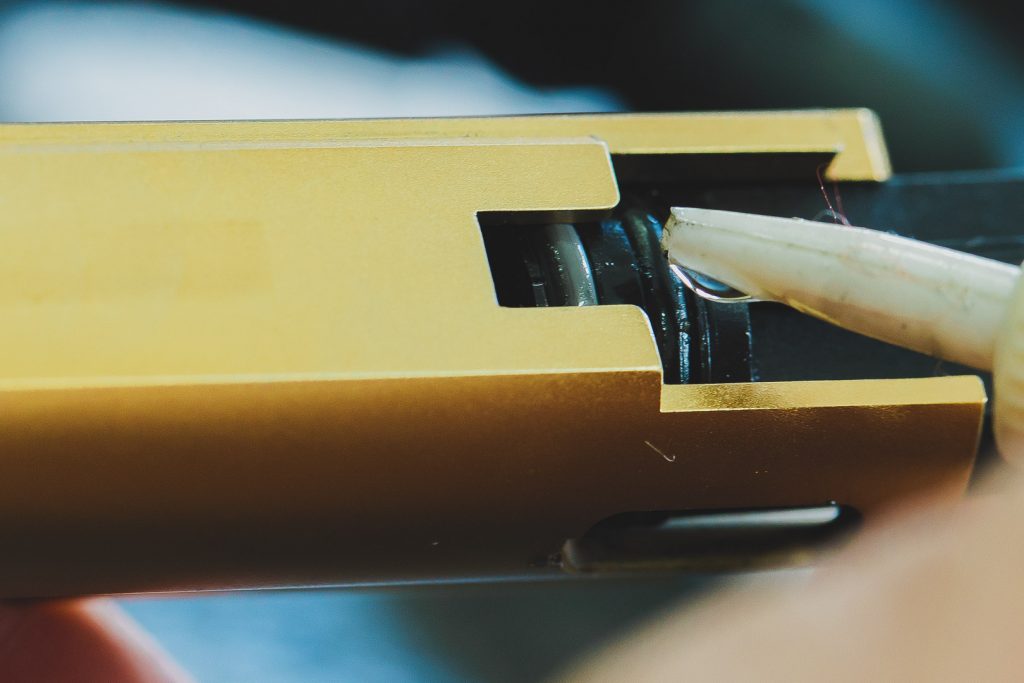

Along with the gun's inner barrel, there are a number of other internal components within your airsoft gun that will require frequent lubrication to continue functioning properly. These components can differ from gun to gun depending on the model that you own, and the process of accessing them can differ as well. For basic lubrication, though, all you have to do is access the gun's action either through the magazine well or by sliding back the bolt. Spraying a little lubricant up through the magazine well or into the bolt assembly will go a long way toward keeping your gun's internal components well lubricated. Occasionally, like in the case of gas pistols or rifles, you will want to disassemble your gun and more properly lubricate its internal components, and we'll explain how to do this to each type of clean maintain airsoft gun in the next section.

Platform-Specific Maintenance and Cleaning

A big part of knowing how to clean and maintain airsoft gun is knowing how to disassemble and reassemble it again so that you are able to access and clean all of its internal components. While this may sound a little daunting if you don't have much experience working with airsoft guns, the good news is that disassembling and reassembling an airsoft gun is typically a relatively straightforward process. With that said, the exact steps you will need to follow depends on the type of airsoft gun that you own, keeping in mind that cleaning the gun's inner barrel and wiping down its exterior components are also steps that need to be followed for every type of airsoft gun.

Electric Airsoft Gun Maintenance

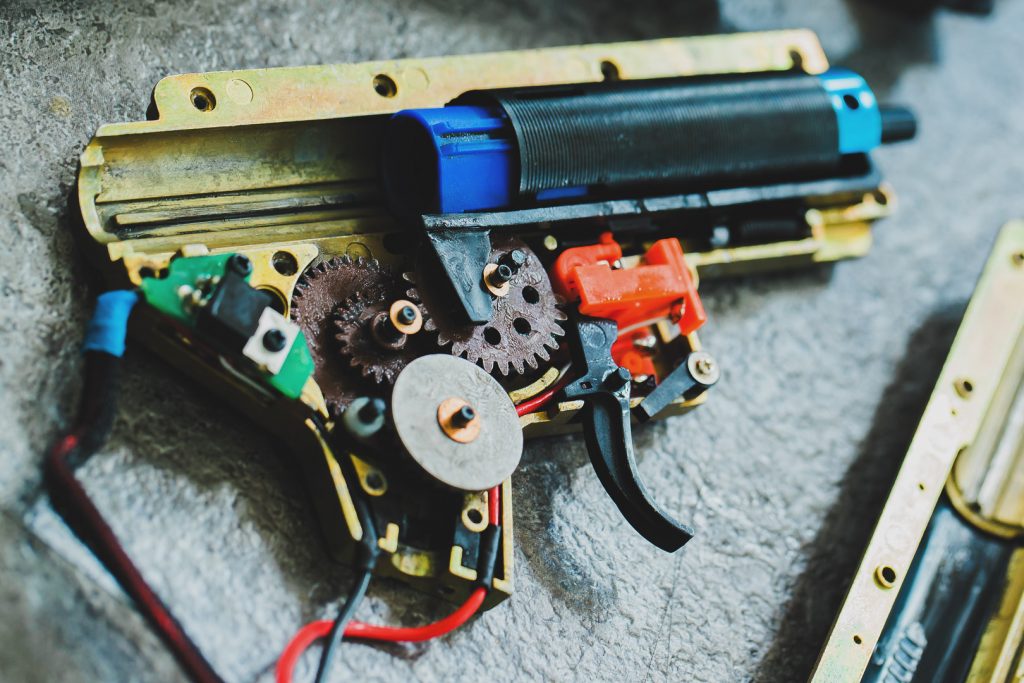

For electric airsoft guns, AEG guns, the biggest challenge is conducting regular maintenance to the gearbox. Though there are many different versions, the maintenance process is more or less the same. Disassemble and reassembling a gearbox can be tricky; if you aren't comfortable doing it yourself, be sure to bring it over to a reputable airsoft tech to do it for you.

Start by carefully disassembling the AEG to take out the gearbox and motor. Some AEGs may not have a gearbox. If so, just completely remove all the internal parts. Be sure to remember how to reassemble them back, label the parts if you have to.

Next, degrease all the moving parts. The gears can be soaked in cleaners like acetone, or other degrease solution, or you can just use a piece of tissue and some wiping alcohol to clean all the internal parts. Be aware that some plastic/ rubber parts may not react well to the cleaning solutions, so be sure to choose one that can move oil/ grease without dissolving plastic or rubber.

Once all of the parts have been degreased, dry them using a rag then reapply a thin layer of grease/ lubricant to all moving parts. In this part you will need to be careful, you will need to apply just the right amount of grease; not too much, not too little. Too little lubrication will have no effect and could speed up wear and tear. Too much grease could gunk up the gearbox, excess grease might block some of the electronics causing potential malfunction.

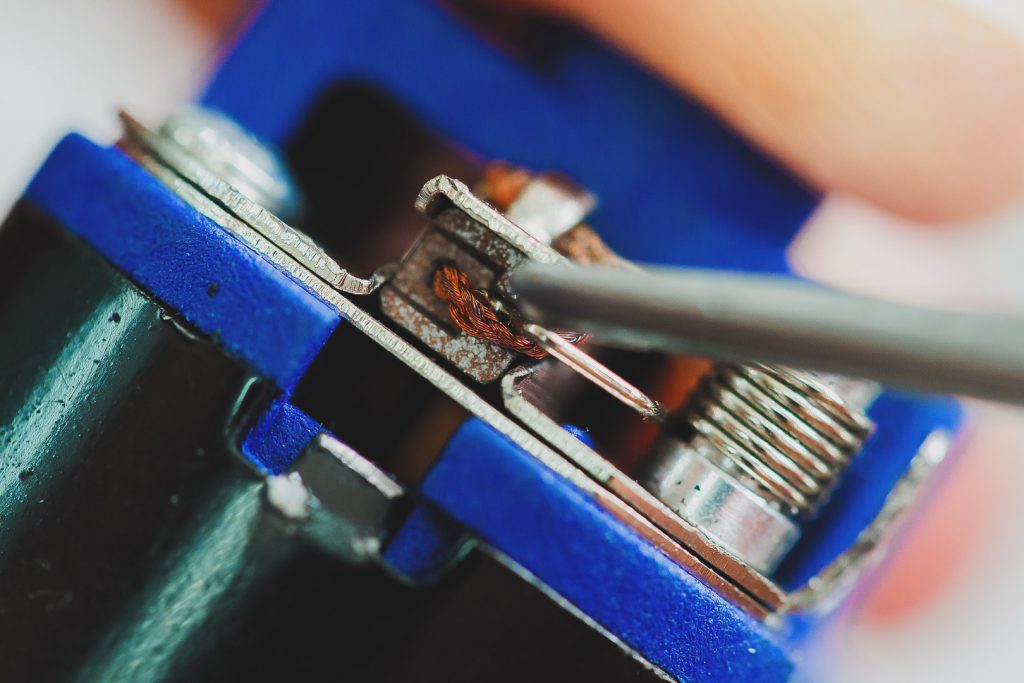

While everything is disassembled, take a minute to check the motor's condition. Unless it is a brushless motor, you will want to see if the carbon brush is depleted or not. Brushed motors have carbon brushes on them and will slowly deplete when used. If the carbon brush is almost depleted, it is a good idea to replace it with a new motor (be sure to get one with the same RPM unless you are upgrading it). Also, check the pinion gear on the motor to see if there are any microfractures/cracks on it.

The final step is to reassemble everything back together. Put all the internal parts back into the gearbox and assemble the AEG back to an airsoft gun. Afterward, plug in the battery fire a few rounds just to make sure it is running fine and smooth. After that, you are done!

Gas Gun Maintenance

The internal mechanisms inside gas airsoft guns are not quite as complex as those inside an AEG, making gas guns a little easier to disassemble and maintain airsoft guns. Start by removing the bolt carrier group assembly from your gun then dissembling it into its individual components. Next, follow the same process for degreasing these parts that you would follow for an AEG.

Once these components have been degreased, dry them off and apply a thin layer of lubricant to each part. For gas guns, it's also important to spay a little silicone gun oil inside the nozzle seal of your magazines and inside the piston of your gun's bolt assembly in order to prevent plastic parts inside these components from drying out. Once this is complete, you are ready to reassemble your gun and fire off a few rounds to make sure everything is functioning properly when finding out how to clean and maintain an airsoft gun.

Spring Gun Maintenance

Cleaning and maintaining a spring-powered airsoft gun is quite similar to the process of cleaning a gas gun, but even simpler. With spring airsoft guns, all you need to do is disable the gun's bolt assembly, degrease and lubricate each individual component, then reassemble the gun. Spring airsoft guns do not require the application of silicone oil like gas guns and do not have a gearbox that needs to be dissembled and cleaned like AEGs, so once you've cleaned all of the components inside the gun's bolt assembly you are ready to put the gun back together. Do pay special attention to the spring inside the gun, though, and make sure that it is well lubricated so that it will clean and maintain its airsoft spring strength for as long as possible.